Expertise Tailored to Your Needs

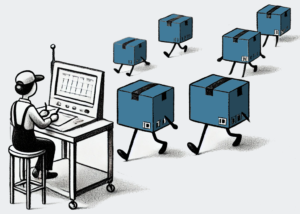

At Arete Intralogistics Consulting, we specialize in providing and guiding customized intralogistics solutions that streamline your warehouse operations and business needs. With years of experience and a deep understanding of Warehouse Execution, Control and Management Systems we are your trusted partner in achieving a successful go-live and operational excellence.

Areas of Expertise

The expertise Arete offers in both Warehouse Execution Systems (WES) and Warehouse Control Systems (WCS) is unparalleled. We excel in all aspects of WES & WCS, including:

both Warehouse Execution Systems (WES) and Warehouse Control Systems (WCS) is unparalleled. We excel in all aspects of WES & WCS, including:

- Automation/Equipment Coordination

- Volumetrix & Order Planning

- Order Start Regulations

- Real-Time Control

- Task Execution

- Error Handlings

- Labor Management

- Workflow Optimization

- Order Management

Especially Arete’s team’s thorough experience with Knapp‘s systems positions us uniquely to get out the full capabilities when using KiSoft-One © in your facility, providing significant advantages during the design and implementation phases, as well as for post-implementation projects such as system extensions.

Our comprehensive knowledge includes both system handling and user interface proficiency, ensuring that we deliver exceptional consulting solutions tailored to your specific needs.

The WMS consulting solutions you receive are tailored to meet the unique needs of your business. Arete offers end-to-end support, from system selection, design and implementation to ongoing maintenance and optimization.

The ultimate goal is to help you achieve greater inventory accuracy, improved order fulfillment, and increased operational efficiency. The extensive experience in Warehouse Management Systems we offer, caters to both automated and non-automated warehouse environments. Arete excels in all facets of WMS, providing comprehensive support solutions tailored to enhance your warehouse operations.

- Inventory Management

- Order Fulfillment

- Slotting

- Interface to ERP

- Interface and coordination with WCS systems

- Receiving and Putaway

- Materialflow and Replenishment Processes

- Volumetrix

- Picking and Packing

- Shipping and Loading Management

- Reporting and Analytics

These and numerous other WMS-related functionalities are part of our core consulting business.

Arete’s team’s deep experience with various WMS platforms, including those integrated with automation solutions like Knapp’s WMS KiSoft-One, allows us to leverage it’s full capabilities and therefore provide significant advantages during each phase of your project.

Whether you are operating a fully automated warehouse or a traditional manual setup, the WMS expertise you receive at Arete will help you achieve optimal efficiency and productivity during any phase of your project and even afterwards.

Through our support a wealth of expertise in the field of automated picking systems is brought into your projects and facilities, providing cutting-edge solutions that enhance operational efficiency and accuracy in your facility.

Our consulting services cover a broad range of automated picking technologies, ensuring that our c lients benefit from the most advanced and reliable systems available.

lients benefit from the most advanced and reliable systems available.

We have extensive experience with a wide range of automated picking systems, including but not limited to:

- A-Frame Dispensers

- Auto Pickers

- Picking Robots

- Automated Guided Vehicles (AGVs)

- Pick-to-Light Solutions

- Pocket Picking Systems

This is just a selection of the systems we are experienced in working with.

This expertise is particularly vital during the design and implementation phases but also when analyzing specific requirements, optimizations and during post-go-live support.

Arete is committed to delivering exceptional consulting services for any automated picking systems. The long-standing hands-on experience and deep knowledge of these technologies enable Arete’s team to provide solutions that drive operational excellence and competitive advantage for our clients.

Our consulting services encompass a broad array of automatic storage technologies, ensuring that our clients benefit from the most advanced and reliable systems when it comes to storing goods in their warehouse.

A variety of automatic storage systems from our portfolio of expertise, including but not limited to:

- AS/RS Crane Solutions

- AS/RS Shuttle Solutions (such as the Knapp OSR Shuttle Evo)

- Fastbox Solutions

- Single Item AS/RS solutions (such as the Knapp-Store)

- Pallet Flow Racking

Arete’s practical experience with these technologies enables the delivery of the right solutions tailored to the specific needs of your put-away, goods-in and material flow requirements.

Choosing and designing the right system or combination of storage and retrieval systems is one of the most vital parts when designing your system.

This choice becomes even more complex when considering future extension possibilities, whether physical or logical ones.

Arete’s support will ease this decision-making process, and together, we will make sure that the optimal storage and retrieval solution for your business is designed, implemented and fully realized.

The type of conveyor and layout you choose for your facility greatly depends on a handful of factors.

From tote conveyors (e.g. streamline) , to pallet conveyor (e.g. powerline) to pocket systems popular in the fashion industry, we have the experience to consult on the optimal layout while also take future extensions into account.

Stackers, palletizers, closers, strappers, paper handling systems but also autonomous mobile robots (AMRs) — whatever your facility needs, the question is whether these are really needed, and how they can be best integrated into your facility. This includes both their physical location within your facility and their logical place in your warehouse process.

Selecting the right conveyor and components depend on understanding your specific application needs, considering load characteristics, environmental conditions, available space, and ensuring energy efficiency and safety compliance.

Backed by a long time in the industry, we work with you to make those choices to achieve the operational benefits you are looking for. Our partnership will allow you to select conveyor system solutions that address the specific needs, knowing full well that all of the questions at hand will be taken care of.

Goods-to-person solutions are perfect fits for warehouses with high order volumes and a wide range of SKU’s, due to their increased picking efficiency and accuracy realized by delivering items directly to the operator.

The efficiency is enhanced by the reduced time and effort required for workers to locate and retrieve items.

Furthermore, it enhances order fulfillment accuracy:

The right items are delivered directly to the operator, thereby minimizing errors and optimizing space utilization through high-density storage solutions.

Particularly in e-commerce and retail businesses where speed of order fulfillment and minimal rate of errors are very critical, these systems are proven beneficial.

By evaluating factors like order volume, SKU variety, fulfilment speeds, operational flexibility and many more, Arete will support you in choosing, designing, implementing and supporting the solution that aligns with your operational needs and business goals.

There’s a number of picking variants that make even more sense for certain business cases than goods-to-person or fully automated solutions do.

Whether you’re dealing with large dimension variations, low order volumes for specific SKU’s or budget constraints, there is a right solution for every case – it just needs to be found, correctly designed and implemented.

Picking methods like

- RF Manual Picking

- Parallel/Cart Picking

- Pick-to-Carton

- Pick-to-Belt

- Pick-by-Label

- Pick-to-Light

combined with Batch or Zone picking are part of our expertise rich Portfolio.

All these methods can be tailored to maximize efficiency and accuracy, regardless of your warehouse size or complexity.

By leveraging Arete’s expertise, you receive the needed help to design and implement the most effective picking strategy to meet your unique operational requirements

Automated solutions in the Mail Order and Central Fill Pharmacy sectors have seen significant growth over the past decade. Advances in robotics, artificial intelligence, and pharmacy management software have driven this growth, leading to increased efficiency, accuracy, and scalability.

With advanced technologies come new manufacturers, correspondingly a broader spectrum of solutions and thus more complexity.

Arete’s expertise in this sector lies primarily with solutions supplied by KNAPP.

This also includes the products supplied by Knapp for this sector and their functionalities integrated into the overall system:

- Automatic Tablet Dispensers (ATD)

- KMeD

- Knapp Store

- PV2

- OSR (industry variant)

Over the past few years through hands-on implementing and supporting projects in this sector, Arete’s team gained in-depth knowledge regarding the features brought by Warehouse Execution Systems (such as KiSoft-One).

This accumulated knowledge supports Arete’s partners to automate their central fill pharmacies and mail order facilities with a well-designed system and a straightforward implementation phase.

Pocket and garment automation systems are among others useful in apparel- and e-commerce fulfillment centers with the goal to optimize storage, sorting, order accuracy and speed in operations that have wide SKU variability and numerous smaller orders.

Additionally, pocket fulfillment systems enable effective inventory management and reverse logistics through fast handling of store replenishment and returns.

Our experience portfolio includes (especially with DFT):

- Consolidation Buffers (such as AutoPocket®)

- Dynamic buffers

- Intelligent Matrix Sorters

- Garmet Sorters (such as GarmentFlow®)

- Goods-to-Person solutions

In the fashion industry these systems have long been indispensable for handling hanging and flat-packed goods such as shirts, shoes, and accessories.

Recently they have even found valuable use cases in the healthcare industry.

This demonstrates how, when all criteria are carefully considered, there is a suitable automation solution for every business case. With Arete’s consulting support, all criteria will be accordingly considered when designing your fulfillment center, ensuring the creation of the perfect solution for your business needs.

With the Drug Supply Chain Security Act (DSCSA) to be in full effect by November 2024, the serialization of all prescription drugs with their National Drug Codes will be mandatory.

Therefore, having the correct vision solutions for your warehouse or pharmacy is now more crucial than ever. This mandate will require registration, verification, and traceability of serial numbers, lot numbers and expiration dates during the receiving process.

Whether you are implementing a solution in a new facility or an extension of your existing system, Arete can support you across the entire process of decision, design, and implementation.

Our expertise lies in the vision-related products offered by Knapp, which Arete’s team had strong history with:

- Vision Central Belt (VCB)

- Vision Item Check (VIC)

- Manual Item Check (MIC)

- Itemizer

- Vision Scan Tunnels

Arete will support you to choose the correct vision check solution for your facility and ensure seamless compliance with DSCSA requirements.

The expertise Arete offers in both Warehouse Execution Systems (WES) and Warehouse Control Systems (WCS) is unparalleled. We excel in all aspects of WES and WCS, including:

The expertise Arete offers in both Warehouse Execution Systems (WES) and Warehouse Control Systems (WCS) is unparalleled. We excel in all aspects of WES and WCS, including:

- Automation/Equipment Coordination

- Volumetrix & Order Planning

- Order Start Regulations

- Real-Time Control

- Task Execution

- Error Handlings

- Labor Management

- Workflow Optimization

- Order Management

Especially our deep experience with Knapp’s systems positions us uniquely to leverage the full capabilities of KiSoft-One ©, providing significant advantages during the design and engineering phases, as well as for change requests and system extensions post-implementation.

Our comprehensive knowledge encompasses both system handling and user interface proficiency, ensuring that we deliver exceptional consulting solutions tailored to your specific needs.

The WMS consulting solutions you receive are tailored to meet the unique needs of your business. We offer end-to-end support, from system selection, design and implementation to ongoing maintenance and optimization. Our goal is to help you achieve greater inventory accuracy, improved order fulfillment, and increased operational efficiency. The extensive experience in Warehouse Management Systems (WMS) we offer, caters to both automated and non-automated warehouse environments. We excel in all facets of WMS, providing comprehensive solutions tailored to enhance your warehouse operations.

These and numerous other WMS-related functionalities are part of our core consulting business. Our deep experience with various WMS platforms, including those integrated with automation solutions like Knapp’s WMS KiSoft-One, allows us to leverage it’s full capabilities and therefore provide significant advantages during the design and engineering phases. Whether you are operating a fully automated warehouse or a traditional setup, the WMS expertise you receive at Arete will help you achieve optimal efficiency and productivity during any phase of your project and even afterwards.

- Inventory Management

- Order Fulfillment

- Slotting

- Interface to ERP

- Interface and coordination with WCS systems

- Receiving and Putaway

- Materialflow and Replenishment Processes

- Volumetrix

- Picking and Packing

- Shipping and Loading Management

- Reporting and Analytics

Through our support a wealth of expertise in the field of automated picking systems is brought into your projects and facilities, providing cutting-edge solutions that enhance operational efficiency and accuracy in your facility.

Our consulting services cover a broad range of automated picking technologies, ensuring that our clients benefit from the most advanced and reliable systems available.

We have extensive experience with a wide range of automated picking systems, including but not limited to:

- Central Belt Systems

- Autopickers & A-Frames

- PiE Robots

- Knapp-Stores

- Indu-Stores

- Pocket Picking Systems

This is just a selection of the systems we are experienced in working with.

This expertise is particularly vital during the design and implementation phases but also when analyzing specific client requirements, optimizations and during post-go-live support.

At Arete, we are committed to delivering exceptional consulting services for any automated picking systems. Our extensive hands-on experience and deep knowledge of various technologies enable us to provide solutions that drive operational excellence and competitive advantage for our clients.

Our consulting services encompass a broad array of automatic storage technologies, ensuring that our clients benefit from the most advanced and reliable systems when it comes to storing goods in their warehouse.

A variety of automatic storage systems from our portfolio of expertise, including but not limited to:

- OSR Shuttle Evo

- OSR PiE

- OSR 2D Shuttle Evo

- OSR Vario Shuttle

- Fastbox

- ASRS Crane Solutions

Our practical experience with these technologies enables us to deliver the right solutions tailored to the specific needs of your put-away, goods-in and material flow requirements.

Choosing and designing the right system or combination of storage and retrieval systems is one of the most vital parts when designing your system.

This choice becomes even more complex when considering future extension possibilities, whether physical or logical ones.

Our support will ease this decision-making process, and together, we will make sure that the optimal storage and retrieval solution for your business is designed, implemented and fully realized.

Stackers, palletizers, closers, strappers, paper handling systems but also autonomous mobile robots (AMRs) like the Open Shuttle — whatever your facility needs, the question is whether these are really needed, and how they can be best integrated into your facility. This includes both their physical location within your facility and their logical place in your warehouse process.

Selecting the right conveyor system depends on understanding your specific application needs, considering load characteristics, environmental conditions, available space, and ensuring energy efficiency and safety compliance.

Backed by a long time in the industry, we work with you to make those choices to achieve the operational benefits you are looking for. Our partnership will allow you to select conveyor system solutions that address the specific needs, knowing full well that all of the questions at hand will be taken care of.

Stackers, palletizers, closers, strappers, paper handling systems but also autonomous mobile robots (AMRs) like the Open Shuttle — whatever your facility needs, the question is whether these are really needed, and how they can be best integrated into your facility. This includes both their physical location within your facility and their logical place in your warehouse process.

Selecting the right conveyor system depends on understanding your specific application needs, considering load characteristics, environmental conditions, available space, and ensuring energy efficiency and safety compliance.

Backed by a long time in the industry, we work with you to make those choices to achieve the operational benefits you are looking for. Our partnership will allow you to select conveyor system solutions that address the specific needs, knowing full well that all of the questions at hand will be taken care of.

Goods-to-person solutions are perfect fits for warehouses with high order volumes and a wide range of SKU’s, due to their increased picking efficiency and accuracy realized by delivering items directly to the operator.

The efficiency is enhanced by the reduced time and effort required for workers to locate and retrieve items. Furthermore, it enhances order fulfillment accuracy:

The right items are delivered directly to the operator, thereby minimizing errors and optimizing space utilization through high-density storage solutions.

Particularly in e-commerce and retail businesses where speed of order fulfillment and minimal rate of errors are very critical, these systems are proven beneficial.

By evaluating factors like order volume, SKU variety, fulfilment speeds, operational flexibility and many more, Arete will support you in choosing, designing, implementing and supporting the solution that aligns with your operational needs and business goals.

There’s a number of picking variants that make even more sense for certain business cases than goods-to-person or fully automated solutions do.

Whether you’re dealing with large dimension variations, low order volumes for specific SKU’s or budget constraints, there is a right solution for every case – it just needs to be found, correctly designed and implemented.

Picking methods like

- RF Manual Picking

- Parallel Picking

- Pick-to-Carton

- Pick-to-Belt

- Pick-by-Label

- Pick-to-Light

combined with Batch or Zone picking are part of our expertise rich Portfolio.

All these methods can be tailored to maximize efficiency and accuracy, regardless of your warehouse size or complexity.

By leveraging our expertise, we can help you design and implement the most effective picking strategy to meet your unique operational requirements

Automated solutions in the Mail Order and Central Fill Pharmacy sectors have seen significant growth over the past decade. Advances in robotics, artificial intelligence, and pharmacy management software have driven this growth, leading to increased efficiency, accuracy, and scalability.

With advanced technologies come new manufacturers, correspondingly a broader spectrum of solutions and thus more complexity.

Our expertise in this sector lies primarily with solutions supplied by KNAPP.

This also includes the products supplied by Knapp for this sector and their functionalities integrated into the overall system:

- ATD

- KMeD

- Knapp Store

- PV2

- OSR (industry variant)

Over the past few years through hands-on implementing and supporting projects in this sector, we have gained in-depth knowledge regarding the features brought by KiSoft-One’s Pharmacy Execution System, its system handling, component realization, and the best uses.

This accumulated knowledge enables our partners to automate their central fill pharmacies and mail order facilities with a well-designed system and a straightforward implementation phase.

Pocket and garment automation systems are among others useful in apparel- and e-commerce fulfillment centers with the goal to optimize storage, sorting, order accuracy and speed in operations that have wide SKU variability and numerous smaller orders.

Additionally, pocket fulfillment systems enable effective inventory management and reverse logistics through fast handling of store replenishment and returns.

Our experience portfolio includes (especially with DFT):

- Consolidation Buffers (such as AutoPocket®)

- Dynamic buffers

- Intelligent Matrix Sorters

- Garmet Sorters (such as GarmentFlow®)

- Goods-to-Person solutions (such as Pick-it-Easy Pocket)

In the fashion industry these systems have long been indispensable for handling hanging and flat-packed goods such as shirts, shoes, and accessories.

Recently they have even found valuable use cases in the healthcare industry.

This demonstrates how, when all criteria are carefully considered, there is a suitable automation solution for every business case. With Arete’s consulting support, all criteria will be accordingly considered when designing your fulfillment center, ensuring the creation of the perfect solution for your business needs.

With the Drug Supply Chain Security Act (DSCSA) to be in full effect by November 2024, the serialization of all prescription drugs with their National Drug Codes will be mandatory.

Therefore, having the correct vision solutions for your warehouse or pharmacy is now more crucial than ever. This mandate will require registration, verification, and traceability of serial numbers, lot numbers and expiration dates during the receiving process.

Whether you are implementing a solution in a new facility or an extension of your existing system, Arete can support you across the entire process of decision, design, and implementation.

Our expertise lies in the vision-related products offered by Knapp, which we’ve had strong history with:

- Vision Central Belt (VCB)

- Vision Item Check (VIC)

- Itemizer

- Multiscan

- Vision Scan Tunnels

We will support you to choose the correct vision check solution for your facility and ensure seamless compliance with DSCSA requirements.